Abstract

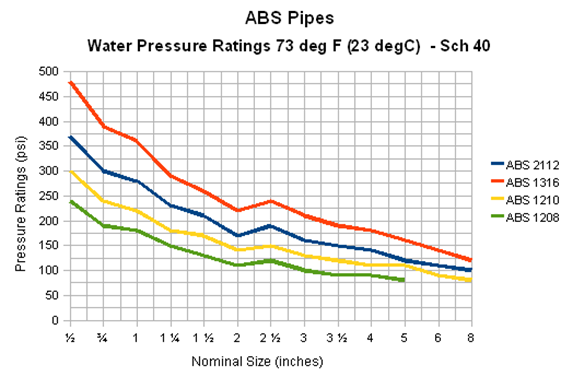

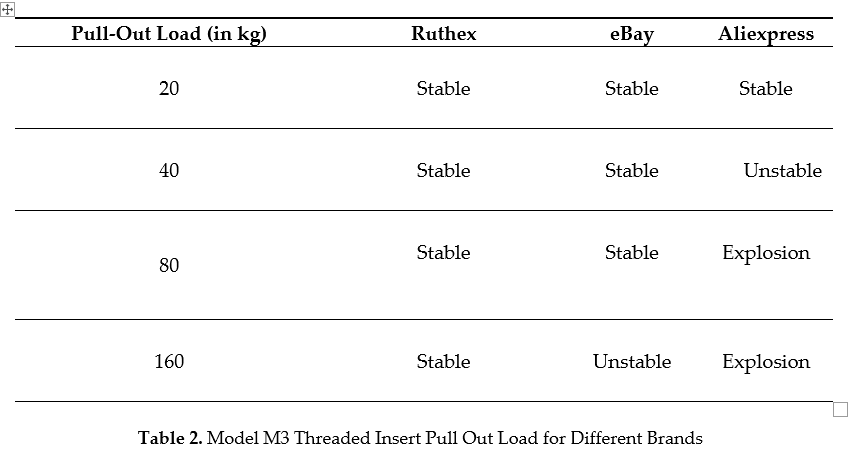

This study investigates the creation of a custom pneumatic tank for a VEX Robotics “Over and Under” competition robot, with a focus on using Acrylonitrile Butadiene Styrene (ABS) for its durability in high-pressure situations. Recognizing the limitations of standard tanks in space-restricted settings, the research details the design and fabrication processes that leverage advanced modeling to ensure the tank's fit within the robot's compact build. Testing across various pressures confirms that the tailored ABS tank not only meets spatial requirements but also outperforms traditional tanks in durability and efficiency. The findings emphasize the importance of targeted material choice and custom design in producing pneumatic components for robots where space is at a premium, without sacrificing performance.